The Difference Between Single-layer and Multi-layer PCB

When it comes to printed circuit boards, one of the first considerations before designing is whether to use single or multi-layered PCBs. These categories are used by the circuit board industry to determine the complexity of a board’s structure. Each type of PCB has a different price point and use; however, they are now widely used in electronics and applications such as computers, mobile phones, radio equipment, and so on.

We will see the difference between single-layer and multi-layer PCBs from this blog article reference. If you want to buy PCB, unitepcb is the leading PCB manufacturer in China.

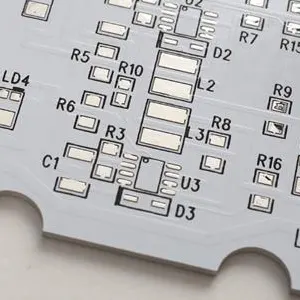

Single-Layer PCBs

Single-layer PCBs are much easier to work with than 2-layer PCBs due to their simple design. We believe it is so simple because it only has one conductive layer and the necessary tooling holes, but no through via holes for conductive purposes. This feature determines that the manufacturing process is very simple, and thus the cost is very low.

Single-sided circuit boards may not be as complex as their counterparts, but they power a wide range of everyday electronics. Because they are so inexpensive to produce, they can be found in mass production devices such as camera systems, audio equipment, power supplies, calculators, solid state drives, and printers surveillance.

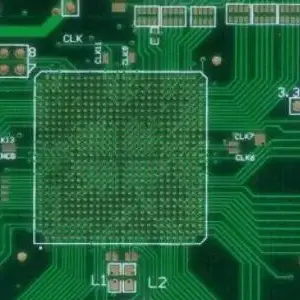

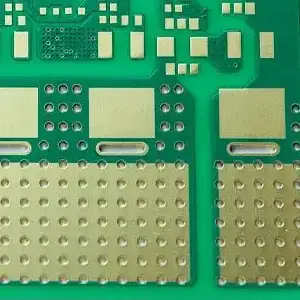

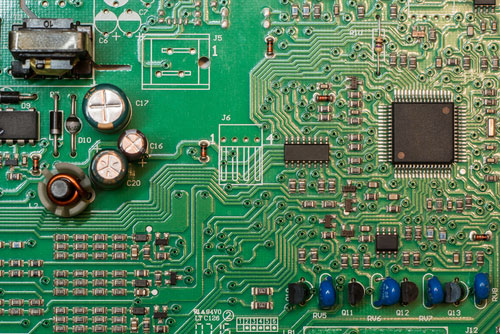

Multi layer PCBs

Multilayer PCBs have one or more conductor patterns inside the board, increasing the amount of space available for wiring. By laminating or gluing together multiple double-sided circuit boards with insulating layers in between. PCBs with 4 to 8 layers are commonly used because they provide the right amount of complexity for most applications. However, depending on the device, more layers are possible. These will most likely differ depending on the device. Because of the various demands of the circuit, some smartphones, for example, are said to use 12 layers. They frequently have an even number of layers because odd layers can cause problems with the circuit board. This includes issues such as warping and twisting after soldering, as well as no cost savings because they are not standard to produce.

Because of the high capacity of multilayer PCBs, there are complex technologies such as computers and data servers. They can be found in electronic devices like:

● Fiber optics

● Smartphones

● GPS systems

● Scientific and space technology

● Heart rate monitors

● Atomic accelerators

Single-Layer PCBs: Weighing the Pros and Cons

To determine whether a single-layer PCB is right for you, consider your project’s requirements and whether single-sided boards have the capabilities you require. Because of their low cost and quick production times, they are typically the board of choice for simpler devices. However, for more complex projects, they frequently do not provide enough functionality.

Before deciding to use single-layer PCBs, weigh the benefits and drawbacks. To summarize, the benefits and drawbacks of single-layer PCBs are as follows:

Pros:

● Lower cost

● Easier design and production

● Capability to produce in large quantities

● Reduced lead time

Cons:

● Oversimplified for complex projects

● Reduced operating capacity

● Slower speed

● Greater size

● Higher weight

Multi-Layer PCBs: Weighing the Pros and Cons

Do multi-layer printed circuit boards suit your electronic device? They very well may be if the device is on the more complex end of the spectrum. However, be prepared to pay a premium for the increased functionality and other benefits. Consider the advantages and disadvantages of using multi-layer PCBs, as well as the needs of your project and the resources you have available to purchase the boards. The following are the benefits and drawbacks of multi-layer PCBs:

Pros:

● Capability to deal with more complex functionality

● Improved quality

● Increased power, capacity, and speed

● Increased durability

● Smaller in size and weight

● A single point of connection

Cons:

● Increased costs

● More difficult design and production

● Limited availability

● Extended lead times

● More difficult repairs

Why are Multi-Layer PCBs Commonly Used?

For a variety of applications, both single layer and multi layer printed circuit boards are commonly used. Single layer PCBs are used for simpler devices with limited functionality, whereas multi layer PCBs are used for more complex devices with more functionality. Due to the need for smaller, more intricate devices in various industries and sectors, PCB manufacturers have seen an increase in demand for multilayer boards.

Deciding Whether You Need Single-Layer or Multi-Layer PCBs

To determine whether you need single-layer or multi-layer printed circuit boards, consider your project’s requirements and which type best meets them. Ask yourself the following five questions:

1. What level of functionality am I looking for? If the situation is more complicated, you may require multiple layers.

2. What is the maximum size of the board? Multi-layer boards pack more functionality into a smaller footprint.

3. Is durability important? If so, choose multi-layering.

4. What is my financial situation? Single-layer boards are best for smaller budgets.

5. How soon do I need the PCBs? When compared to multi-layer printed circuit boards, single-layer printed circuit boards have a shorter lead time.

You will also have to deal with more technical requirements questions, such as the operation frequency, density, and signal layers required. The answers to these questions will help you determine whether you need a board with one, two, four, or more layers.

Final thoughts

When creating printed circuit boards, it is critical to understand the differences between types of PCBs so that you can select the best one for your application. unitepcb is here to assist you in obtaining the PCBs you require and to provide guidance to get you started in the right direction.