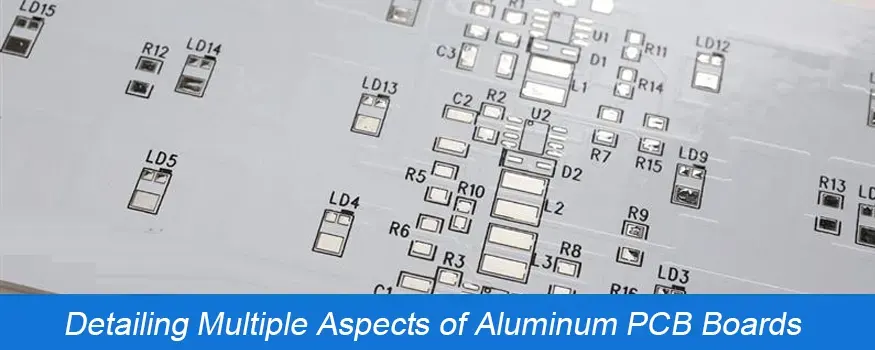

Detailing Multiple Aspects of Aluminum PCB Boards

Aluminum PCB is the most common type of metal PCB and is useful in a wide range of applications. including telecommunications, computers, computers, air conditioner variable-frequency modules, high-power LED lighting, and power. In this post, I’ll go over aluminum PCB boards in great detail.

What is Aluminum PCB?

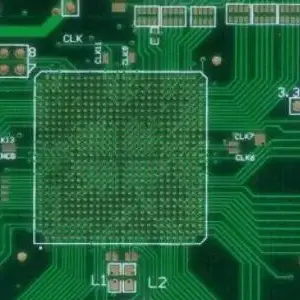

The layout of an aluminum PCB is similar to that of any other PCB. Over it is a layer or layers of copper, solder mask, and silkscreen. An aluminum circuit board, on the other hand, has a metal substrate rather than a fiberglass or plastic substrate. This base is primarily composed of aluminum. The metal core can be all metal or a combination of fiberglass and aluminum. Aluminum PCBs are typically single-sided but can also be double-sided. Multilayer aluminum PCBs are extremely difficult to produce.

What are the Different Types of Aluminum PCBs?

The type of aluminum circuit board chosen is largely determined by the application. Aluminum PCB boards are classified into three types:

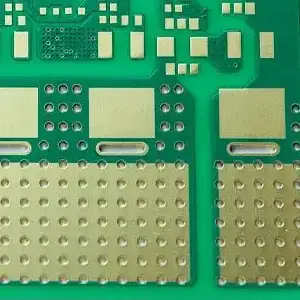

1. Through-hole Aluminum PCBs

The aluminum in through-hole aluminum circuit boards is pre-drilled. The hole is then backfilled with a dielectric.

2. Flexible Aluminum PCBs

Flexible dielectrics, which provide a high level of flexibility, thermal conductivity, and electrical insulation, are used in these PCBs. When these dielectrics are combined with aluminum material, the resulting product is highly flexible and can be formed into a variety of shapes. This helps to eliminate the need for expensive connectors and fixtures.

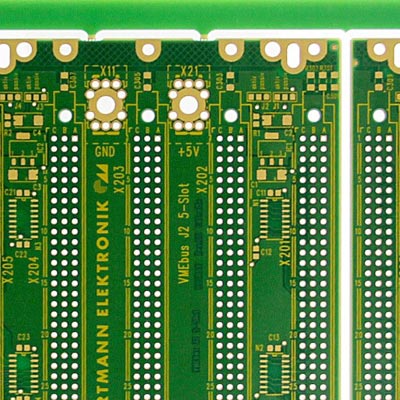

3. Hybrid Aluminum PCBs

These aluminum PCBs are commonly used in RF applications and are known to provide better thermal performance when compared to standard FR4 products.

Structure of Aluminum PCBs

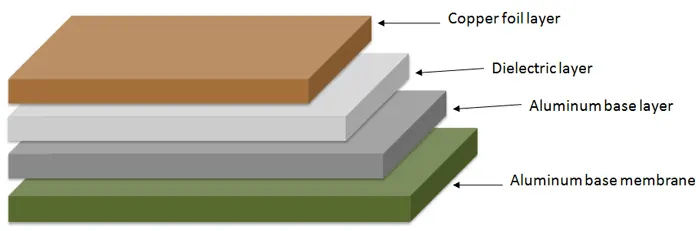

Aluminum PCBs are CCLs that are made of aluminum (CCL is a type of base material of PCBs). Aluminum PCBs are very similar to FR4 PCBs. Aluminum PCB boards have a four-layered basic structure. It is made up of a copper foil layer, a dielectric layer, an aluminum base layer, and an aluminum base membrane.

● Copper Foil Layer: The copper layer used is thicker than standard CCLs ( 1oz-10oz). A thicker copper layer means more current carrying capacity.

● Dielectric Layer: The Dielectric layer is a thermally conductive layer that ranges in thickness from 50m to 200m. It had low thermal resistance and was appropriate for its application.

● Aluminum Base: The third layer is the aluminum base, which is made up of aluminum substrate. It has an extremely high thermal conductivity.

● Layer of Aluminum Base Membrane: Aluminum base membrane is selective. It serves as a barrier between the aluminum surface and scraping and unwanted etching. It is classified into two types: lower than 120 degrees and around 250 degrees (anti-high temperature)

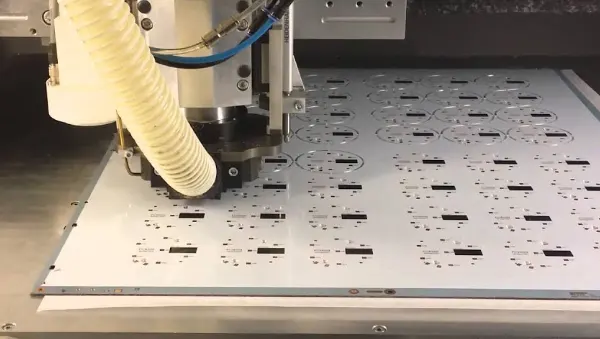

How is Aluminum PCB Made?

Aluminum printed circuit boards are made up of metal-based seals that are protected by copper foil circuit layers. They are made of alloy plates containing magnesium, aluminum, and silumin (Al-Mg-Si). Aluminum PCB boards provide good thermal potential, electrical insulation, and high machining performance, and they differ from other PCBs in a variety of ways.

Base layer

This foundation is made of an aluminum alloy substrate. Because of the use of aluminum, this type of PCB is an excellent choice for through-hole technology, which will be discussed later in this article.

Thermal insulation layers

This is a critical component of the PCB. It contains a ceramic polymer with excellent thermal resistance and viscoelastic properties that protects the PCB from mechanical and thermal stresses.

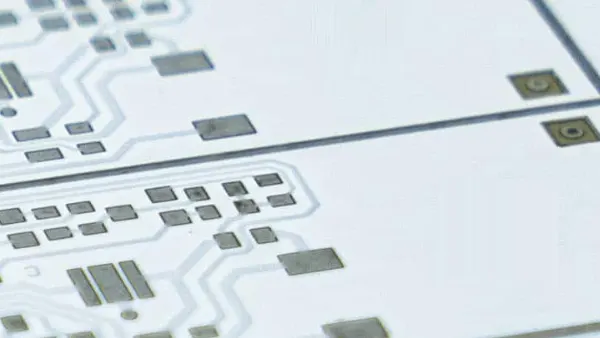

Circuit layer

This layer includes the copper foil mentioned earlier in this article. Copper foils weighing one to ten ounces are commonly used by PCB manufacturers.

As current flows through the circuits, the insulation’s dielectric layer absorbs heat. This is transferred to the aluminum layer, which dissipates the heat.

Aiming for the highest possible light output results in increased heat. Improved thermal resistance PCBs increase the life of your finished product. Heat mitigation, superior protection, and part reliability will all be provided by a skilled manufacturer.

Performance of Aluminum PCBs

Dimensional Stability

Aluminum PCBs have dimensional stability and a consistent size. When heated from 30-140 degrees, for example, their dimensions only changed by 2.5%-3.0%.

Thermal Dissipation

When compared to ordinary FR4 PCBs, the performance of aluminum PCBs in dissolving heat is quite good. A 1.5mm thick FR4 PCB, for example, has a thermal resistance of 20-22 degrees per watt, whereas a 1.5mm thick aluminum PCB has a thermal resistance of approximately 1-2 degrees per watt.

Thermal Expansion

Each substance has a different coefficient of thermal expansion. Copper (18ppm/C) and aluminum (22ppm/C) have comparable CTEs. Aluminum PCBs do not have severe contraction or development issues because they perform well in terms of thermal dissipation. They perform admirably, are long-lasting, and are dependable.

Advantages of aluminum PCB

● Because of the high level of heat dissipation provided by aluminum PCB boards, they are an excellent choice for applications involving high temperatures and long operating hours.

● Another advantage that makes aluminum effective and economical is its low cost. Aluminum is a common metal that is easily accessible and can be mined and refined at a low cost.

● Because aluminum is non-toxic, it is environmentally friendly and an excellent choice for applications involving product recycling.

● Aluminum-based products have significantly greater strength and durability than fiberglass and ceramic materials.

● Aluminum is a very strong and sturdy material that can withstand more pressure and stress when it comes to manufacturing and material handling than other metals.

● Aluminum is extremely light. It increases the product’s strength and durability without adding weight.

● The thermal conductance of the used dielectric is 5 to 10 times that of old epoxy glass.

● Thermal transfer is more efficient and dependable than traditional PCB.

● Heat dissipation is significantly better than in standard FR-4 constructions.

Application of Aluminum PCB

1. Audio device: input amplifier, output amplifier, balanced amplifier, audio amplifier, pre-amplifier, and power amplifier.

2. Power supply: switching regulators, DC/AC converters, SW regulators, and so on.

3. Communication electronic equipment: a high-frequency amplifier, filtering devices, and a transmitter circuit.

4. Automation equipment for the office: motor drives, etc.

5. Automobile: ignition, voltage regulator, automatic safety control system, lighting conversion system.

6. Computer: CPU board, floppy disk drive, power supply devices, and so on.

7. Power Modules: Inverters, solid-state relays, and rectifier bridges are examples of power modules.

8. LED Display 8 (two modes: LED display; display with LED light source)

9. Lighting: With the promotion of energy-saving lamps, the market has welcomed a variety of energy-saving LED lights, so aluminum substrates for LED lights have widespread applications.

Unitepcb offers competitively priced custom high-quality Aluminum-based PCBs and Metal Core PCBs. We offer a wide range of service types to meet your diverse needs, including prototype, low volume, and mass volume production. If you’re looking for aluminum PCB boards, learn more about us!