Weight and Thickness of Heavy Copper PCB

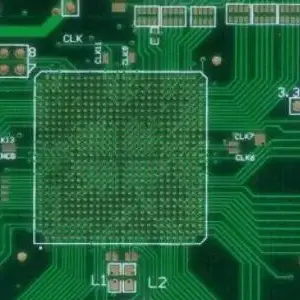

Electric current flows through the copper layers of a PCB. As a result, selecting the incorrect copper thickness can degrade the performance of a circuit assembly. You can choose the correct copper weight for your design with confidence if you understand the relationship between copper weight and signal transmission and PCB fabrication cost. As a result, the copper weight selected may have an impact on the overall process of PCB assembly fabrication. A brief explanation will assist you in making the best decision.

What Is Copper Weight/Copper Thickness?

In PCB production, the standard copper thickness is 1 oz. In general, the thickness of copper is measured in ounces. What is the relationship between the weight and thickness of copper? When a specific weight of copper is rolled to occupy 1 square foot, the thickness is measured. So, if one ounce of copper is rolled out to cover one square foot, the resulting foil thickness is 1.37 mils (0.0348 mm).

Importance of Copper Thickness

Aside from the PCB dimensions, the single most common property that designers change is the copper thickness. Changing the copper weight can cause unexpected changes in the board’s other properties, necessitating a DFM/DFA review. These modifications include:

Copper Thickness: This is self-evident, as copper weight is directly proportional to copper thickness—more weight equals thicker copper, and vice versa.

Via Annular Ring: As the copper weight changes, so does the minimum annular ring required for a via. Because the drilled hole is not always perfectly centered, this is an important design specification because it affects the reliability of an electrical connection to a via.

Track Width and Spacing: The copper weight has a significant impact on the track width and spacing on a particular layer. This, in turn, affects the board stackup and impedance control calculations. Changing the copper weight can thus have a cascading effect for tight track width and spacing, as well as impedance control.

Minimum Conductor Clearance: The amount of copper on a layer influences the minimum conductor clearance on that layer. Heavier copper weight results in a thicker copper layer, which necessitates deeper etching and deeper undercuts. Designers must provide wider conductor clearance to compensate for the deeper undercuts.

PCB cost: A heavier copper weight indicates that the PCB has more copper in that layer. If the PCB is multi-layered, the amount of copper increases proportionally, which could result in a significant increase in project cost.

Copper Thickness Conversion Chart

| oz | 1 | 1.5 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| mils | 1.37 | 2.06 | 2.74 | 4.11 | 5.48 | 6.85 | 8.22 | 9.59 | 10.96 | 12.33 |

| inch | 0.00137 | 0.00206 | 0.00274 | 0.00411 | 0.00548 | 0.00685 | 0.00822 | 0.00959 | 0.01096 | 0.01233 |

| mm | 0.0348 | 0.0522 | 0.0696 | 0.1044 | 0.1392 | 0.1740 | 0.2088 | 0.2436 | 0.2784 | 0.3132 |

| µm | 34.80 | 52.20 | 69.60 | 104.39 | 139.19 | 173.99 | 208.79 | 243.59 | 278.38 | 313.18 |

The Role of Copper Weight in PCB Fabrication

The thickness of a PCB’s copper traces, and thus of the copper layer, determines its current carrying capacity.

The required trace width for impedance-controlled boards is an important determinant of copper thickness. Furthermore, the weight of the PCB, the type of connectors that will be assembled onto the board, and component compatibility requirements are all important considerations.

The heavier the copper weight, the better the conductors, and the greater the overall thickness of your circuit board. When designing the circuit board, you must pay close attention to the copper thickness. Heavy copper’s thickness and width can cause a difference in current-carrying potentials.

The presence of copper on the board increases the board’s tolerance capacity. A heavy copper PCB is required when using a circuit board for industrial products. The heavy copper weight in a specific layer of circuitry protects the board. Most products in the aerospace and defense industries require heavy copper PCB. A heavy copper PCB has another advantage. The copper-plated vias aid in the passage of high current through your board. It aids heat transfer to the outer heat sink.

What Is the Difference Between Copper PCB and Heavy Copper PCB?

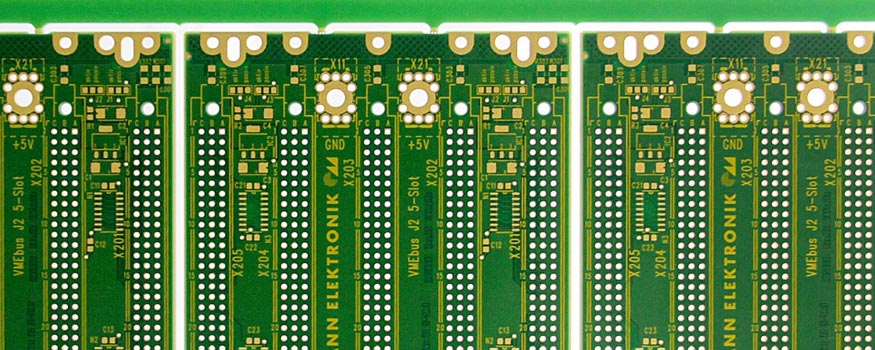

Copper PCB and heavy copper PCB appear to have similar names, and many people believe they are the same PCB. The two, however, actually refer to distinct concepts. The following UnitePCB will explain the distinction between copper PCB and heavy copper PCB in depth.

Copper PCB: A copper-based PCB is referred to as a copper PCB. The use of copper as the substrate improves heat dissipation and extends the life of PCB components. The copper substrate allows heat to be transferred quickly from the PCB to the outside, such as a heat sink or a metal case, for example. Because copper has a thermal conductivity several times that of aluminum or other metals, up to 401 W/M.K.

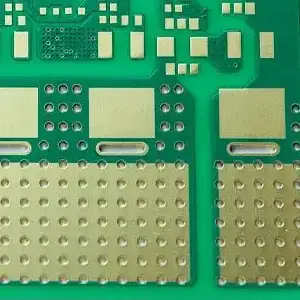

Heavy copper PCB: Heavy copper PCB, also known as thick copper PCB, is a PCB with a copper thickness greater than 3OZ. The substrate can be aluminum or copper, or it can be fr4. The thick copper allows the PCB to carry a high current. Please keep in mind that the thick copper mentioned here refers to the thickness of the copper foil on the PCB, not the thickness of the PCB itself. Copper foil can be thickened on both aluminum PCB and FR4 PCB.

Copper Thickness & PCB Fabrication

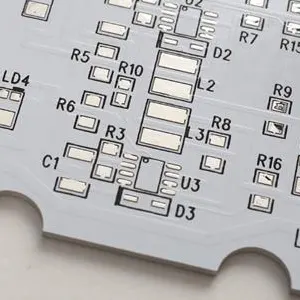

The PCB industry’s most common copper weight is 1 oz, which results in a finished copper thickness of 1.37 mils. In practice, the manufacturer increases the initial copper weight while fabricating the PCB. As a result, when submitting Gerber files, the designer must indicate the finished or plated value of copper weight for their PCB.

PCB manufacturing entails a combination of etching and plating copper processes. Manufacturers start with circuit layers made of thin sheets of copper foil, typically 1 oz, which they etch to remove unwanted copper before plating to add copper thickness to the various traces, pads, planes, and plated through holes. The PCB is completed by laminating the circuit layers into a complete package on an epoxy-based substrate.

Manufacturers will not charge any extra fees for PCBs with a copper weight of 1 oz. Above 1 oz, however, they will usually add some extra cost and lead time. Manufacturers will usually assist customers in determining the additional cost and lead time if they select copper weights greater than 1 oz. Aside from the additional cost and lead time, copper thickness greater than 1 oz increases shipping charges as the weight of PCBs increases.

The additional cost for copper thickness greater than 1 oz stems from the need for additional labor, process engineering, and quality assurance. For example, increasing the thickness of the copper cladding on the laminate necessitates more etching time while adhering to specific DFM guidelines. The thicker copper affects the thermal profile of the board, causing it to absorb significant amounts of heat during the reflow stage, necessitating more care during the assembly process.

Advantages and Uses of Heavy Copper Circuit Boards

The primary advantage of heavy copper circuit boards is their ability to withstand repeated exposure to high current, high temperatures, and thermal cycling, which can destroy a standard circuit board in seconds. The heavy copper board has a high tolerance capacity, making it suitable for use in harsh environments, such as defense and aerospace industry products. Some of the additional benefits of heavy copper circuit boards include:

● Small product size due to the use of multiple copper weights on the same layer of circuitry.

● Heavy copper-plated vias conduct the elevated current through the PCB and aid in heat transfer to an outer heat sink.

● planar transformers with high power density onboard.

Heavy copper PCBs are used in a variety of applications, including planar transformers, heat dissipation, high power distribution, power converters, and so on. Heavy copper-clad boards are in high demand in computer, automotive, military, and industrial controls. Heavy copper printed circuit boards are also used in the following applications:

● Power supplies and converters

● Power distribution

● Welding equipment

● Automotive industry

● Manufacturers of solar panels, etc.

Heavy copper PCBs are more expensive to produce than regular PCBs, depending on the design requirements. As a result, the more complicated the design, the more expensive it is to produce a heavy copper PCB.

Get a Quote for Custom Thick Copper PCB

You should have a basic understanding of heavy copper PCB based on the information presented above. Please contact us if you want to learn more about heavy copper PCB or get the most recent heavy copper PCB price. Alternatively, you can upload your Gerber file to our quick quote page. The professional customer service team at UnitePCB will respond quickly, offering suggestions and preferential pricing.