Advantages & Disadvantages of Multilayer Printed Circuit Boards

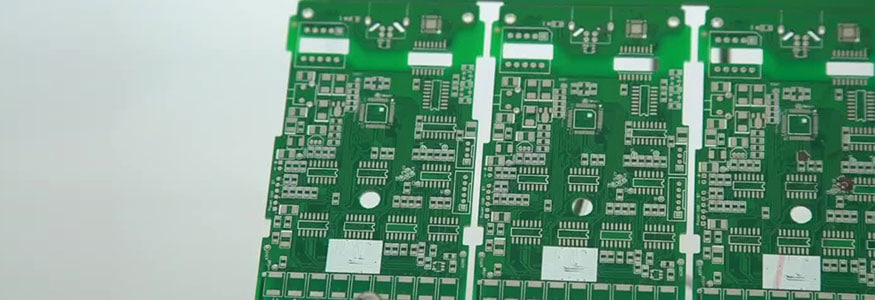

Printed circuit boards (PCBs) are the foundation of most electronics today, determining basic functions via component combinations and wiring mechanisms. Most PCBs were relatively simple and limited by manufacturing techniques in the past, whereas today’s PCBs are much more complex. PCBs are much more varied in today’s world of electronics, ranging from advanced flexible options to odd-shaped varieties. Multilayered PCBs, on the other hand, are extremely popular.

Continue reading to learn more about multilayer PCBs, their benefits and drawbacks in the world of modern electronics.

What Is a Multilayer PCB?

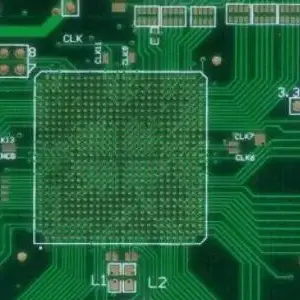

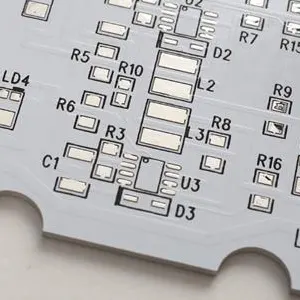

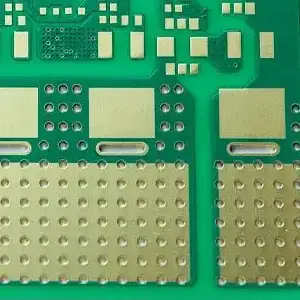

A multilayer PCB is defined as a PCB with three or more conductive copper foil layers. These are made up of several layers of double-sided circuit boards that have been laminated and glued together with layers of heat-protective insulation in between. The entire structure is designed so that two layers are placed on the PCB’s surface sides to connect to the environment. All electrical connections between layers are made using vias, which include plating through holes, blind and buried vias. The use of this method results in the creation of highly complex PCBs of varying sizes.

Advantages of Multilayer PCBs

The demand for multilayer boards is increasing rapidly for most PCB manufacturers. This rising demand is being driven by the need for smaller, lighter boards in electrical devices, military equipment, healthcare miniaturization, and an expanding market for smart devices integrated into home automation systems.

Smartphones and computers, with their need for compactness and light weight while providing sophisticated functionality, are ideal applications for multilayer PCBs.

Over and above saving space and weight, there are numerous technical advantages to using multilayer designs:

1. Boards can increase functionality by incorporating multiple layers on a single PCB.

2. Multilayer board manufacturing processes result in high-quality, dependable end products.

3. Because of their inherent electrical properties, multilayer boards provide high capacity and high speed in a smaller footprint.

4. Increased assembly density

5. The number of connectors required for multiple separate PCBs is reduced or eliminated, simplifying construction and reducing weight even further.

6. Multilayer PCBs are available in rigid and flexible construction. However, keep in mind that the more layers in a flex PCB, the less flexible it becomes.

Disadvantages of Multilayer PCBs

Every technology has advantages and disadvantages, and multilayer PCBs are not exempt from drawbacks:

1. Cost – One of the most significant disadvantages of designing and implementing multilayer PCBs is the cost. Because these boards are manufactured using specialized processes, fabricators must invest significantly to provide these services. As a result, multilayer boards are more expensive than traditional single or double-sided boards.

2. Service availability – not all PCB manufacturers have committed to manufacturing these complex boards, limiting PCB designers’ resource options.

3. The compactness of multilayer boards raises design concerns for issues such as crosstalk and impedance.

4. As functionality increases, so does the need for more extensive testing of a single PCB. Because of the complexity of the manufacturing process, manufacturing cycles may also be longer.

5. Repairing a multilayer printed circuit board can be extremely difficult, if not impossible. Failure of a multilayer board is therefore costly, as it may need to be completely replaced.

6. Because interconnection between layers is critical for board function, microvia design and fabrication, as well as overall density, are critical.

Multi-Layer Printed Circuit Boards at Work

Multi-layer printed circuit boards have become the natural choice in any industry where mobility is stressed. This could be most noticeable in consumer electronics, such as smartwatches, smartphones, and computer electronics. GPS devices are also clear winners in terms of multi-layer PCBs, as these devices must not only be highly portable but also durable and reliable.

Many industrial applications, in addition to consumer applications, now rely on multi-layer printed circuit boards. Multi-layer printed circuit boards are increasingly being used in automotive, military, aerospace, and medical applications for many of the same reasons.

Conclusion

The disadvantages can be easily addressed if the multilayer PCB is carefully designed and manufactured. These multilayered boards are undeniably popular. They are used in medical equipment, military devices, home automation, and many other applications.

Overall, multi-layer circuit boards are often higher in quality than standard PCBs because they require more design, planning, and investment. Although the price may be higher, the functionality and performance more than compensate. These boards are typically designed as a single unit, making it much easier to mount the board onto the final product.