What Is the Difference between PCB and PCBA?

PCBs are the building blocks of modern electronic devices. In the electronics industry, the terms printed circuit board (PCB) and printed circuit board assembly (PCBA) are both important. Both are critical for the fabrication and design of a complete circuit board.

In this article, we’ll go over what PCBs and PCBAs are, how they’re related, and the key differences between the two terms so you can confidently use them when placing orders and describing products.

What Is a PCB?

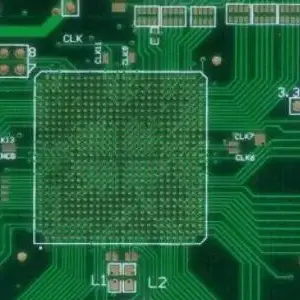

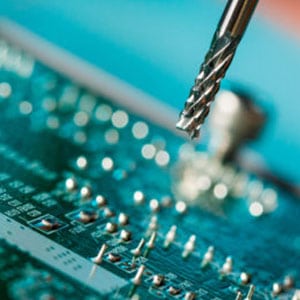

PCBs serve as a mechanical foundation for various electrical components to be mounted in order to complete the intended circuit. The boards are made of laminate material, such as fiberglass or composite epoxy, and have conductive pathways that connect various parts of the board. These pathways are printed or inscribed onto the board in accordance with the PCB design.

The following are some of the most common types of printed circuit boards:

● Single-layer

● Multi-layer

● Rigid-flex PCB

● Flexible

● Heavy copper PCB

● Multilayer flexible PCB

With all of these options, manufacturers and product designers can create a wide range of electronic displays, standalone devices, and other products for consumer, commercial, and industrial applications.

What Is a PCBA?

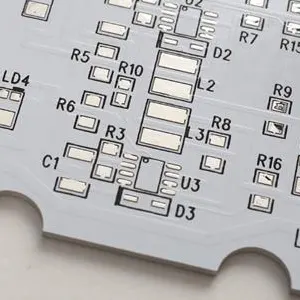

PCBA (Printed Circuit Board Assembly) is the board that results from printing solder paste on the PCB and then mounting various components such as resistors, ICs (Integrated Circuits), capacitors, and any other components such as transformers, depending on the application and desired characteristics of the board. A PCBA is typically heated in a reflow furnace to form a mechanical connection between the PCB and the components.

Components of PCBA

An empty PCB board is stuffed or populated with electronic components during the assembly process to form a functional printed circuit assembly (PCA), also known as the PCBA. Electronic components are mounted in holes surrounded by conductive pads using through-hole technology. The components are placed on the PCB using SMT to ensure that the pins align with the conductive pads. When electronic components are anchored to either side of the board, the components on one side of the board must be glued to the board before soldering.

A populated PCBA board can be tested in one of three ways:

● With the power off, the board can be visually inspected or inspected using an automated optical inspection tool.

● An analog signature analysis can be performed while the power is turned off. This type of analysis is known as “power-off testing.”

When the power is turned on, in-circuit testing takes place.

● Finally, a functional test can be performed to determine whether the PCB is performing as intended.

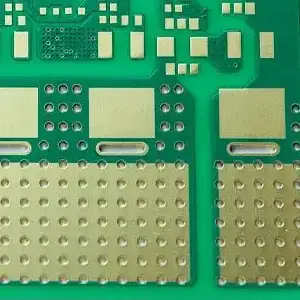

According to the definitions above, the PCBA refers to a complete circuit board or a processing flow, whereas the PCB refers to an empty printed circuit board with no electronic components on it. PCB is a bare board, whereas PCBA is a finished board.

Materials Used

PCB substrates are typically made of fiberglass, composite epoxy, or another laminate material. Copper is commonly used as the conducting material on one or both sides of the board. Copper is also used in the printed circuits, which are plated or etched onto the substrate according to the design. To prevent oxidation, the circuits are coated with tin-lead. To increase conductivity, PCBs have contact fingers on their outer edges that are coated with tin-lead as well as other materials such as nickel and gold.

What Is the Difference Between PCB and PCBA?

PCB stands for circuit board, whereas PCBA stands for circuit board plug-in assembly (SMT). The first is a finished board, and the second is a bare board.

PCB(Printed Circuit Board) (Printed Circuit Board), It is made of epoxy glass resin and is divided into 4, 6, and 8 layers depending on the number of signal layers. The most common are 4 and 6 layers. Chips, for example, are attached to the PCB.

PCBA is a finished circuit board, and it can only be made after the process on the circuit board is completed.

What Are Each Used For?

Printed circuit boards and PCBAs are used in a variety of industries, including:

● Aeronautical industry

● The automobile industry

● Medical sector

● Military

PCBs and PCBAs are found in a wide range of electronic devices. Most homes in this country will have at least a few PCBA-containing devices in each room. Among these devices are the following:

● Mobile phones

● Computers

● Radios

● Televisions

● Printers

● Lighting fixtures

● Home appliances

● Appliances for the laundry room

● Pacemakers

● Medical imaging equipment

● Engine control systems

● Telecommunications towers

● Satellite networks

● Data storage devices

As can be seen, PCBs and PCBAs are used in a wide range of industries and devices. It is obvious, then, that without PCBs and PCBAs, we would be unable to operate a wide range of devices.

Conclusion

The primary distinction between PCB and PCBA is found in the manufacturing mechanism and steps. A generic manufacturing system is used for PCBs. PCBA design, on the other hand, varies depending on the device manufacturer’s requirements. The layout is created in software, and the components are assembled using a machine.

Unitepcb specializes in the design and fabrication of single-layer to multi-layer PCBs for a variety of industries. We can collaborate with you to develop a custom solution for your needs, no matter how complex they are. Contact us today to learn more about our custom PCB capabilities.