How LED Printed Circuit Boards Are Made?

PCB technology has driven many innovative developments, including LED printed circuit board innovations. Though there are many different types of LED lights in the electronic market, they all have a LED PCB at their core. This article will define an LED PCB and explain how it is made.

What Is the Led Printed Circuit Boards?

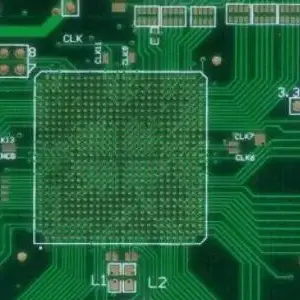

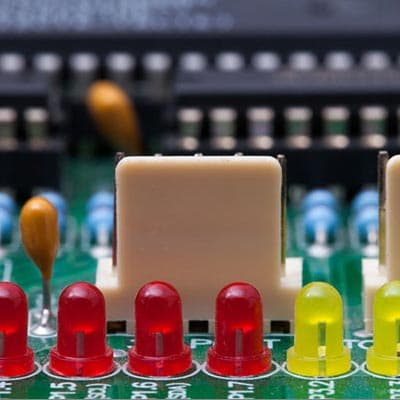

The light-emitting diode, abbreviated as LED, is a popular lighting technique in the digital age. An LED PCB is a printed circuit board designed specifically for LED circuits because they generate a lot of heat energy. LED PCBs are metal-based MCPCBS with an aluminum substrate that has good thermal conductivity.

LED PCBs are constructed with a special thin layer of thermally conductive material that dissipates heat more quickly than standard PCB boards. Aluminum is the most commonly used material in LED circuit boards.

SMD packaging is now the most commonly used packaging form in LED applications. It is generally limited to the light emitted by a single LED component. To achieve sufficient light, multiple LED components would be used in a single light fixture. PCB, like other semiconductor devices, is the best way to connect the LED components electrically. A “LED PCB” is a PCB with LED components soldered to it.

LED PCB Materials

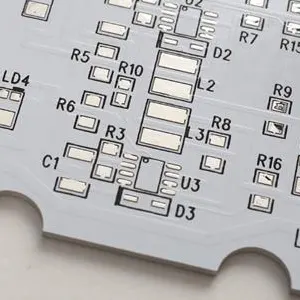

When selecting an LED PCB substrate, you should carefully consider the thermal performance of the material. Weight, size, and cost are also important considerations. The following substrate materials are available:

● FR4 PCB Raw Material

● CEM-1 PCB Raw Material

● CEM-3 PCB Raw Material

● The copper and Aluminum PCB Material

● Copper Core PCB Material

● Ceramic Base PCB Material

Each material has advantages and disadvantages. Metal and ceramic, for example, have better thermal performance than laminate. CEM-1 boards are less expensive but more fragile than FR4 and CEM-3 substrates.

Alumina is one of the materials used in ceramic base PCBs. Other materials with better thermal performance exist, but they are more expensive. A comparable trade-off exists for metal core PCB materials such as aluminum and copper.

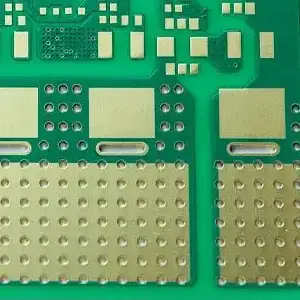

How LED Printed Circuit Boards Are Made

The following are the steps to solder LEDs to a circuit board:

1. Tinning the tip: To solder, you must use a tinned tip. To properly tin the tip of an iron, you must first apply solder to the tip and then coat it thickly. After that, wipe away any excess solder with a wet cloth and reapply a small amount of solder to the tip.

2. Check that the solder surface is clean: For quality results, the surface must be clean. As a result, ensure that any dust, dirt, or element on the surface is removed. More information on cleaning the PCB can be found here.

3. Tin the surfaces: Tin the wires before making the final connection. Solder the wires with a thin layer of solder. Check that the solder is adhered to the wire. Next, make sure the solder pad is tinned as well. Solder the pad with a soldering iron. The solder must flow uniformly across the entire pad. After that, remove the iron and allow the solder to cool.

4. The final connection: Hold the two pieces being soldered with the iron using a tinned tip and surface. Each surface’s solder must flow. Remove the iron quickly, and solder both components after the solder has hardened.

It’s important to note that soldering can be challenging, especially if you’ve never done it before. It is possible that you will cause damage to a component. The important thing to remember is that irons are extremely hot, and LEDs do not like being exposed to excessive heat. As a result, you must exercise extreme caution when setting the temperature on your iron and applying the iron to the surface. Solder should flow and adhere to a surface in a matter of seconds.

The Advantages of LED PCB

There are notable advantages that LED PCB offers. They include:

● Quality performance: LED PCBs are preferred by manufacturers and designers due to their ability to produce high performance. Customers prefer products with high performance because they know their needs will be met. As a result, LED PCBs remain popular because they can provide exactly that.

● Design flexibility: LED PCBs are a better option for those who prefer products with design flexibility. Customers can request that their appliances be designed in the style of their choice. Furthermore, you can gain access to various designs of LED PCBs on the market.

● Energy efficiency: In an age when energy consumption can be costly, it is advantageous to use appliances that save as much energy as possible. The use of LED circuit boards can help users save a significant amount of energy.

● Cost-effectiveness: The cost-effectiveness of LED circuit boards is critical. Any appliance that saves money for both the manufacturer and the customer is a good choice. Consider using LED circuit boards if you want to save money on electrical applications.

● Ease of use: There is no need for training to use the appliance. Because it is simple to use, it is a popular choice among many users. Furthermore, if a problem arises with an LED circuit board, it is simple to diagnose and repair it without requiring the assistance of a technician.

● Less noise: Most electric appliances make annoying noises, but LED circuit boards are different. They produce effective lighting while not making as much noise as other applications.

● It is small: The ability to be small gives an LED PCB a significant advantage. Because of this factor, manufacturers are able to position it well in various areas such as automobiles and others.

● Stable placement: Because the LED circuit board components adhere well to the board, they resist movement. Because of this property, manufacturers are able to use it effectively in moving appliances such as car headlights. Drivers do not have to worry about components being displaced or electrical short circuits forming as the car moves.

● Sizes, intensities, and colors are all available: This advantage allows users to choose what best meets their needs.

● Lightweight: LED PCBs are a viable option for users who prefer to use lightweight appliances.

The application of LED PCB

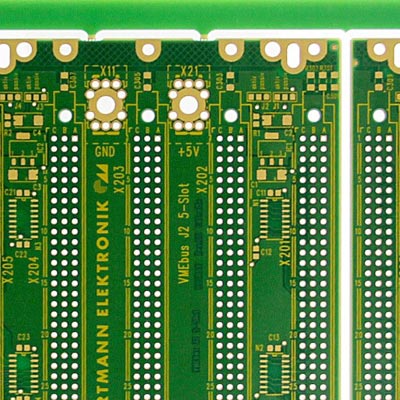

PCB LED lights have high energy efficiency, low cost, and maximum design flexibility, allowing them to be used in a wide range of lighting applications.

● Telecommunications: Due to the surrounding machinery, LED indicators and displays are always used in telecommunications equipment, and they have a great heat transfer ability. As a result, aluminum-based LED PCBs have a beneficial effect on their application.

● Automotive: Aluminum PCB LEDs are also used in automobiles on indicators, brake lights, and headlights, among other applications. Aluminum PCBs are ideal for the automotive industry due to factors such as durability and competitive pricing.

● Computer: LED displays and indicators are becoming increasingly popular in computer applications. Because of the heat sensitivity of computer machinery, aluminum PCB LEDs are an ideal solution. Aside from LED applications, aluminum PCBs are used in computer parts such as power devices and CPU boards due to their ability to dissipate and transfer heat.

● Medical: Lighting tools used in surgeries and medical examinations frequently use high-powered LED lights, and these LED lights frequently use aluminum PCBs, primarily due to the durability and heat transfer capabilities of aluminum PCB LEDs — this ensures that medical equipment functions properly regardless of the number of patients cycling through a medical office. Aside from lighting tools, medical scanning technology frequently employs aluminum PCBs.

Conclusion

LED printed circuit boards are used in a wide range of applications and are found in almost every other circuit. The variety of electrical applications that use LED PCBs demonstrates how popular they are in the electric world. If you are a lighting system OEM in need of high-quality PCBs for your application, make sure you get them from a reputable PCB manufacturer and assembler that provides end-to-end services.