Quality LED PCB Manufacturer and Assembler in China

LEDs are now the most popular type of lighting in the residential, commercial, and industrial sectors due to the obvious benefits they provide. LEDs have many advantages, including high energy efficiency, longer lifespan, low power consumption, and many others. Printed circuit boards (PCBs) have long been used in various electronic devices, and they are now an essential component of LEDs. UnitePCB guarantees the quickest turnaround times on all LED PCBs. It is also critical to manufacturing LED PCBs at a high speed and volume while maintaining quality. UnitePCB manufactures custom PCB LEDs to meet your needs. We are one of the most trusted names in LED PCBs in China because we design them to withstand harsh outdoor environments.

What is LED PCB?

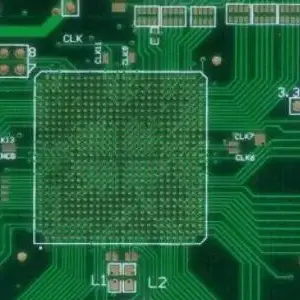

LED stands for light emitting diode, which is a type of semiconductor diode. The LED is soldered to the printed circuit board and contains a chip that generates light when connected electrically. The chip is bonded using a thermal heat sink and a ceramic base. Needless to say, LED PCB is the heart of LED lighting, and an LED PCB generates a lot of heat, making it difficult to cool with traditional methods. As a result of their improved ability to dissipate heat, metal core PCBs are widely used in LED applications. In particular, aluminum is frequently used to fabricate PCB for LED lights. In general, aluminum PCBs have a thin layer of thermally conductive dielectric material that can transfer and dissipate heat much more efficiently than traditional rigid PCBs.

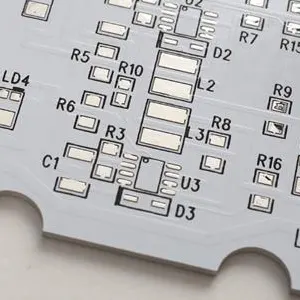

SMD packaging is now the most commonly used packaging form in LED applications. It is generally limited to the light emitted by a single LED component. To achieve sufficient light, multiple LED components would be used in a single light fixture. PCB, like other semiconductor devices, is the best way to connect the LED components electrically. And a PCB with LED components soldered is usually called as “LED PCB”.

The Benefits of LED Circuit Boards

LED lighting and LED PCBs provide numerous advantages that make them useful in a wide range of applications. Among these advantages are the following.

● Reduced power consumption: According to the US Department of Energy, LEDs use at least 75% less energy than incandescent bulbs. Energy Department. By 2027, widespread use of LEDs could result in 348 terawatt-hours of electricity savings, or approximately $30 billion in electricity costs.

● Longer lifespan: LED lights have a lifespan of approximately 25,000 hours, which is 25 times that of incandescent bulbs. When you have to replace bulbs less frequently, you can save a lot of time and money.

● Efficient: Incandescent light bulbs waste approximately 90% of their energy as heat. LEDs, on the other hand, generate very little heat, implying that more energy is directed toward the desired effect of producing light and less is wasted as heat. Reflectors must direct light in the desired direction with non-LED lighting, and some of the light never makes it out of the fixture. LEDs, on the other hand, emit light in a specific direction, making it easier to send it where it needs to go and ensuring that all of the light leaves the fixture.

● Small size: Because LED lights are much smaller than other types of lights, they can be used in small devices such as smartphones as well as as tiny indicator lights. They are also versatile enough to be used in larger applications such as traffic lights and spotlights.

● Mercury-free: Unlike other types of lighting, LED lights do not contain toxic mercury. Because of this, they are safer, more environmentally friendly, and easier to dispose of.

● Radiofrequency-free: Because LED lights do not emit radiofrequency during operation, they will not interfere with other electronic components and devices.

● Environmental friendliness: LEDs use significantly less energy than other types of bulbs, reducing emissions generated during electricity generation. They generate less waste because they last longer.

● Lower costs: The increased efficiency and longer life of LEDs means lower costs because you’ll use less energy and have to replace bulbs less frequently.

Factors to Consider When Designing an LED PCB Board

Materials

The materials used for the printed circuit board must remove and dissipate excess heat, insulate conductors, and permit electrical connections between LED components.

Aluminum serves as the base layer for numerous LED circuit boards. On top of the aluminum base is the dielectric layer, copper circuit layer, and solder mask. This structure is also known as an insulated metal substrate (IMS). The aluminum base is effective at releasing excess heat and aiding thermal management.

Temperature Management

Thermal management is one of the most important aspects of designing LEDs. Inadequate temperature regulation can shorten the device’s lifespan and alter the color purity of the light. Therefore, LED circuit board designs typically incorporate aluminum cores and heat sinks to dissipate as much heat as possible from the components. The arrangement of components and placement of LEDs have an impact on the distribution and removal of heat to the air and should be considered during design.

Route Tracing

Designing traces correctly prevents open and short circuits, crosstalk between circuits, and manufacturing defects. Trace routing ensures that all network connections are attached correctly and do not interfere with other network connections.

Using the correct trace width prevents overheating. Incorporating space for traces and mounting hole considerations into the design also prevents manufacturing issues.

Aluminum metal core PCB

Cores of LED printed circuit boards typically consist of standard epoxy glass or metal. Heat transfer is, as always, essential to the longevity of LED circuit boards. Epoxy glass cores can be less expensive, however.

Metal Core

Aluminum is the most common metal core material for LED printed circuit boards. This metal quickly conducts heat away from the circuit board. This enhances the function of the board’s heat sink to prevent excessive heat from causing damage to the circuit board’s components.

Surface-mounted components are required for these types of PCBs because mounting components through the board could result in short circuits if the solder contacts the metal interior of the board. Since LED components are surface-mounted, however, metal cores suffice for their use.

Normal Glass Epoxy

One of the most significant distinctions between metal and glass cores is their respective heat transfer mechanisms. For example, metal cores do not employ metal vias as heat conductors. Instead, aluminum performs the function. Metal vias remove heat from standard glass epoxy, but not as effectively as metal core PCBs. Metal cores will perform better than standard glass epoxy cores when designing an LED PCB unless cost is the most important factor.

Applications of LED Printed Circuit Boards

At UnitePCB, we provide LED PCB assembly for use in a variety of industries. The following are some important ones.

● Consumer Electronics

● Medical Industry

● Telecommunication Industry

● Elevator Lights

● Headlights

● Street Lights

● Spot Lights

● Automobile Lights

● Solar Energy Products

● Air Landing and Running Lights

● Signal and Traffic Lighting

● Flashlight and Camping Accessories

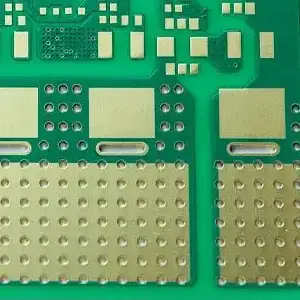

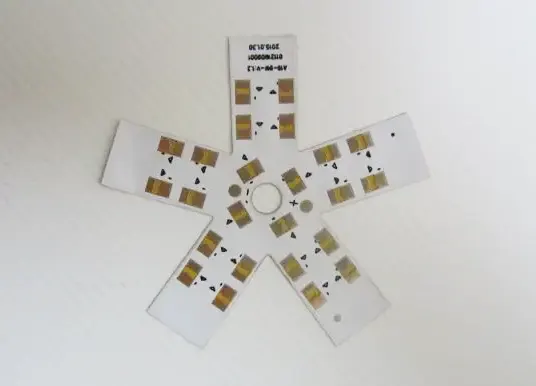

Aluminum LED Circuit Boards

PCBs made of aluminum are the most prevalent type of LED PCB. These circuit boards rest on a base made of aluminum alloy, which typically consists of aluminum, magnesium, and silicon. These LED PCB materials alter the material’s properties to meet the requirements of each application.

PCBs made of aluminum consist of multiple layers.

● The base layer: The base layer consists of an aluminum alloy sheet and serves as the foundation for the remainder of the PCB.

● The thermal insulation layer: Ceramic polymer thermal insulation protects the board from thermal and mechanical damage. As the current flows through the circuits, this layer absorbs any heat emitted and transfers it to the aluminum layer, where it is dissipated.

● The circuit layer: This layer contains the copper circuits laid out in accordance with the circuit design of the LED PCB.

Printed circuit boards have varying numbers of these layers, depending on their design.

There are numerous types of aluminum LED PCBs, each of which has unique properties that make them suitable for a variety of applications.

● Flexible aluminum: Flexible LED PCBs are composed of aluminum, polyimide resin, and ceramic fillers, which provide increased flexibility and insulation while retaining the thermal conductivity of the aluminum. These PCBs can be connected by bending, eliminating the need for connectors, cables, and other hardware. However, their design allows them to bend once and remain in place, as opposed to continually bending. These boards are unlike the standard rigid boards, which are inflexible.

● Hybrid aluminum: These boards are created by fusing an aluminum base metal with a non-thermal material, such as a standard FR-4 board. Utilizing this type of board decreases expenses, increases rigidity, and provides excellent heat dissipation.

● Multilayer aluminum: There are more than two layers of thermally conductive dielectrics on multilayer aluminum PCBs. These boards enable high performance while still providing effective heat dissipation, albeit at a lower rate than other types of boards. These boards are distinct from one- and two-layer PCBs.

Benefits of Aluminum for LED PCBs

Aluminum is one of the most popular materials for LED circuit boards due to its many advantageous properties for LED applications. Excellent heat transfer capabilities may be the most valuable characteristic of aluminum LED PCBs. Consistently high temperatures can harm electronics and LEDs, shortening their lifespan and diminishing their performance, including the quality and color of the lights. Due to these risks, electronic devices must have sufficient heat transference, which describes how well thermal energy or heat energy can move from one location to another. Aluminum readily conducts thermal energy, which enables it to remove heat from components such as LEDs.

The heat transfer properties of aluminum make it possible to mount more LEDs on each board. Because LEDs generate heat, too many can cause excessive heat to accumulate. However, using an aluminum PCB enables you to increase the number of LEDs without sacrificing performance. Also, the longer an electronic device is used, the hotter it becomes. Improving heat transference allows you to operate your device for longer, even continuously, and extends the LEDs’ and device’s overall lifespan.

Our LED PCB Board Capabilities

As an experienced LED PCB Manufacturer, we realize intricate designs. Our extensive LED printed circuit board capabilities include:

● LED circuit boards that are rigid, flexible, and rigid flexible.

● Embedded LED PCB.

● SMD LED circuit boards.

● Metal Core LED circuit boards.

● An extensive variety of coatings, including SMOBC/HASL, electrolytic gold, electroless gold, electroless silver, immersion gold, immersion tin, and OSP.

● Copper or aluminum may be used as the base plate.

● PCB Core Options: FR-4, Epoxies, and Aluminum with Copper Lamination.

● Dielectric thickness:.003 inches

● Lead-free/ROHS-compliant assemblies.

● Automated PCB Optical Inspection, Electrical Testing, and Sample Inspections.

Why choose Unitepcb’s Led Lighting Printed Circuit Board?

As a reliable LED PCB assembly manufacturer in China, we are pleased to offer LED printed circuit boards of superior quality and performance. At UnitePCB, we value our customers above all else. Our specialists interact directly with clients to fully comprehend their needs. In addition to assisting you in the selection process, they are involved in all phases of printed circuit board design, from conceptualization to production and deployment. We are one of the most reliable and trustworthy LED PCB assembly manufacturers in China as a result of our intense passion for PCBs and their technologies, as well as our vast industry experience.