Advantages and Disadvantages of Ceramic Multilayer PCBs

Ceramic circuit boards are durable, reliable, and a great alternative to other electrical components due to the properties of the ceramic materials used in their manufacture. These ceramic boards are made of high-quality industrial materials with metal cores, which distinguishes them from typical ceramics used in home decor, crockery, and flooring. They are also known as green boards, not because of their color, but because they use fewer toxic chemicals and have a lower carbon footprint than traditional counterparts.

Let us examine some of the advantages and disadvantages of a relatively new technology, ceramic multilayer PCB, which is gaining traction.

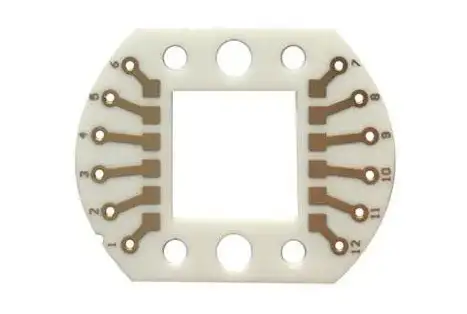

What is Multilayer Ceramic PCB?

A printed circuit board made of ceramic is known as a ceramic PCB. It conducts heat using a ceramic base material such as alumina, aluminum nitride, or beryllium oxide. The thermal conductivity of these materials ranges from 9 to 20 W/m. They enable them to dissipate heat from hot spots across the entire surface. Ceramic PCBs are made from a combination of ceramic powder and an organic binder. They are designed to be thermally conductive and are manufactured using LAM technology. LAM (laser rapid activation metallization) allows for more efficient and simpler construction. Ceramic PCBs provide increased versatility and performance.

Fabrication Methods of Multilayer Ceramic PCB

Thick Film Ceramic Board

These boards are heated to slightly less than a thousand degrees (1000°) by printing gold and dielectric paste on a ceramic base. Copper or gold is used, and nitrogen gas is used to prevent oxidation, resulting in greater durability and quality.

LTCC PCB

LTCC is an abbreviation for low-temperature co-fired ceramic. The traces are made of gold for high thermal conductivity. The boards are heated to 900 degrees Celsius. This type of PCB used co-firing, which involves simultaneously combusting non-glass, glass components, or glass crystals.

PCB HTCC

HTCC is an abbreviation for high-temperature co-fired ceramic. Lubricant, adhesive, plasticizer, solvent, and aluminum oxide are all used. The tracing is made of molybdenum or tungsten, both of which are extremely heat resistant. The temperature ranges from 1600°C to 1700°C. These boards are typically smaller and of higher quality.

Advantages of Ceramic PCBs

Thermal Conductivity is very high

The values range from 25 to 330 W/(mK) depending on the material used (alumina to beryllia, as previously stated). It is more than 20 times greater than that of FR4 PCB. Ceramics performs better and can protect a device from heat damage due to its ability to dispel heat.

Thermal Expansion Coefficient is Low (CTE)

It has strong and outstanding interatomic bonds, allowing it to withstand high temperatures while remaining firm, stable, and consistent even when temperatures change.

Excellent Thermal Insulation

Because ceramic is extremely insulating, heat will be less likely to flow through the substrate, protecting the circuit board’s components from damage or harm.

Inorganic

It can work and be useful for a longer period of time due to its inorganic materials. Also noteworthy is the chemical resistance to erosion.

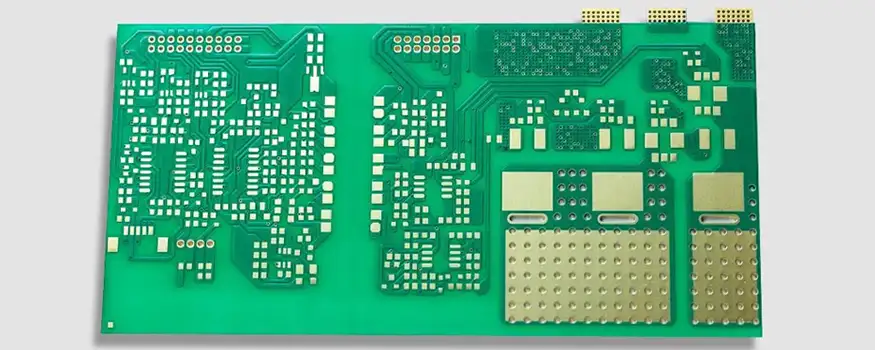

Multi-Layering – A multi-layer ceramic PCB can handle more difficult tasks. Because of the toughness of its material, another layer can be easily added while keeping the other components safe. It’s ideal for heavy-duty applications.

High Frequency

With its dimensional and thermal stability, a ceramic PCB can handle high frequency. This will undoubtedly benefit industries that require high-frequency data and electrical signal transmissions, such as the medical and aerospace sectors.

Cost Effectiveness

It may not be as inexpensive as FR4, but with improved performance and service life, it will undoubtedly last longer. The overall system cost is still lower than metal core PCBs due to its simple design and reduced fabrication.

Disadvantages of Ceramic PCBs

Cost

Ceramic boards are more expensive than traditional boards. It is used primarily in the aerospace and high-tech products for a reason. This is arguably the main disadvantage of ceramic circuit boards. However, when considering its performance, the price is reasonable. In fact, it will save you money on future repairs and provide better customer satisfaction, which will boost the reputation of your brand.

Handling

Ceramic boards are delicate. That they are difficult to handle and necessitate extra effort. As a result, if it is damaged, it will take a long time to repair. Another factor to consider is its size. Ceramic PCBs are small and designed to fit into small spaces. However, considering the service and quality, the effort of handling is worthwhile.

Availability

Ceramic-based circuit boards have a low availability when compared to other types of circuit boards. It’s not something you’ll come across very often. Some online selling services provide ceramic boards, but their quality must be verified. When looking for fine ceramic, it can take some time to find the right board for you. Its scarcity raises the price.

Uses of the Multilayer Ceramic PCB

Given the additional board space and circuitry on the multilayer PCB, it has a variety of applications.

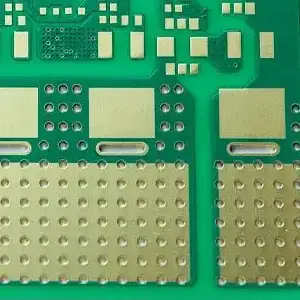

● Memory modules employ multilayer ceramic PCBs. These four-layer modules can be created through the agglomeration of integrated circuits. Because of its multilayer ceramic PCBs, this device has a high density and excellent performance.

● Their application in space developments such as satellite communications systems and space vehicles will be incredible. For these applications, ceramic multilayer printed circuit boards are preferred. This is due to their ability to perform under adversity. Multilayer PCBs are extremely resistant to shocks, vibrations, and high temperatures.

● Multilayered ceramic PCBs are used in electronic devices. Multilayer configurations are useful for connecting more electronics. The performance of the device is improved as a result of this implementation.

● It is also used as an additional application in transceiver modules. A multilayer ceramic PCB is used specifically for radio detection and ranging communication. The module transmits and receives RF signals. Because aluminum nitride has a higher heat conduction capability than alumina, it is used as the ceramic base in this case. Furthermore, it provides an optimal communication path with a low CTE.

● Analog and digital circuits are developed using multilayer ceramic printed circuit boards. As a result, parasitic traits have shown less capacitance. Furthermore, the weight and size of the PCBs have been significantly reduced. Crosstalk and other interference signals have been reduced and, in some cases, eliminated.

Conclusion

A ceramic printed circuit board (PCB) is a type of electronic connector made of ceramic materials. It is primarily used to meet the stringent requirements of the electrical industry. This type of printed circuit board is gaining popularity for a variety of reasons, the most important of which is its superiority over standard or traditional boards. They are made of materials that are less sensitive to temperature changes, chemicals, and water, making them a more viable option for PCB designers as a result of recent market advancements.

If you are looking for ceramic multilayer PCBs, please email us at [email protected] or call us at +86-755-23597842.