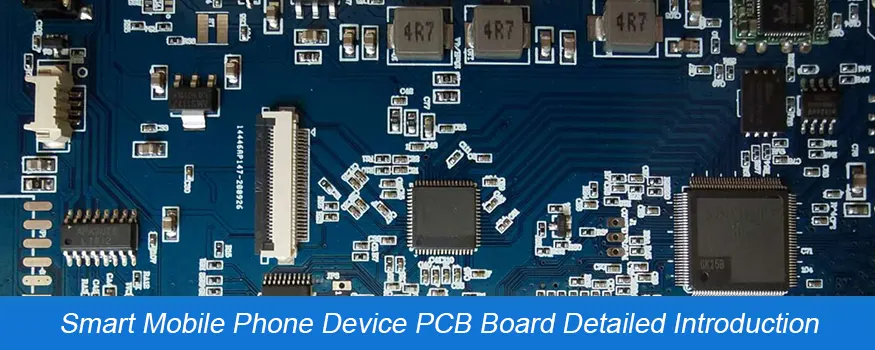

Smart Mobile Phone Device PCB Board Detailed Introduction

PCBs can be present in a wide range of electronic devices, including televisions, computers, and digital cameras as well as smart mobile phones. The circuit board of a cell phone is in all functions, the mind that runs the cell phone. It is the central point of operation for the entire phone. On the circuit board, many components work together to make sure the phone works correctly.

Role of Printed Circuit Boards in the Evolution of Cell Phones

Through the years, technology has provided the world with some significant advancements in the field of communication. Beginning with the very first phone in the 70s to the latest phones in the marketplace in the present, engineers and researchers are always innovating methods of making our phones smaller, more efficient as well as more effective. Printed circuit boards are becoming smaller and more efficient as their capabilities and performance increase.

This allows manufacturers to fit more components into a smaller amount of space, allowing all the features we’ve come to anticipate, including touchscreens, Wi-Fi connections and cameras. As we look to the future, PCBs from consumer electronics have revolutionized the way that our mobile phones, tablets, and even cars interact with the world that surrounds us.

Smart Phone PCB Requirement

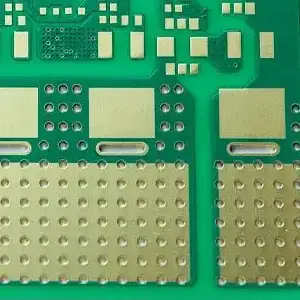

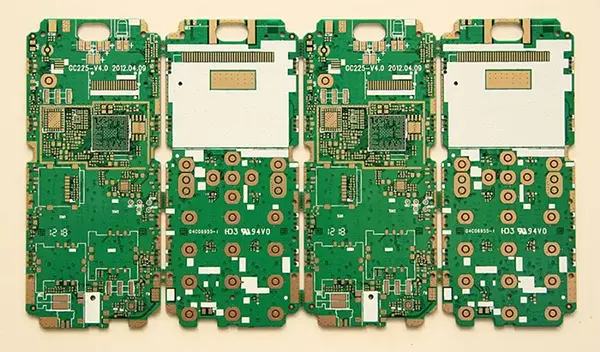

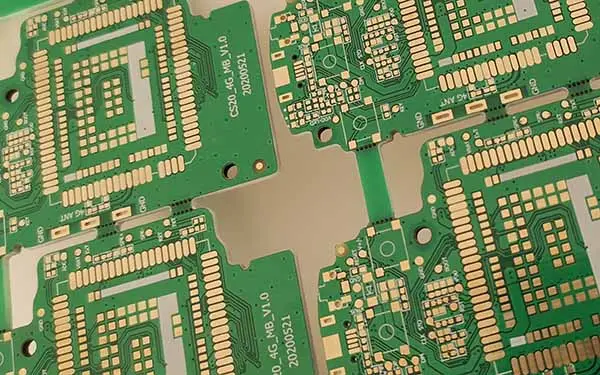

Based on the functions and patterns of the next smartphones Based on the functions and development trends of future smartphones, highly multilayer PCBs are recommended for use as motherboards, and low multilayer PCBs can be used as complementary daughterboards. When it comes to designing motherboards, 10-layer build-up multilayer (BUM) PCBs will be typically chosen. Because of the function integration provided through silicon packaging (SiP), It’s highly likely that the number of layers will remain the same or may be diminished. In 2015, we saw the introduction of 64-bit processors. IC Pin spacings have decreased from 0.4mm to 0.35mm, and the number of layers of the motherboard could rise up to twelve layers or more in the near future.

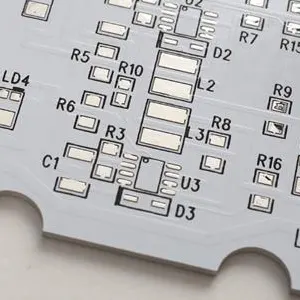

The technology behind PCB is so vital that it plays an essential part in the manufacturing of PCBs effectively and efficiently at a cost-effective. A newer generation of technology called surface mount (SMT) requires designers to be aware of manufacturing issues in the beginning because of its complexity. Any slight modification to designs will cause delays in production and an increase in development costs. Any change in pad position will require rerouting and solder paste stencil manufacturing. Thus, designers need to be attentive to technical issues right from the start. One rule is simple: For manufacturers, it is more beneficial if technological problems are solved early.

How Do Cell Phone Circuit Boards Work?

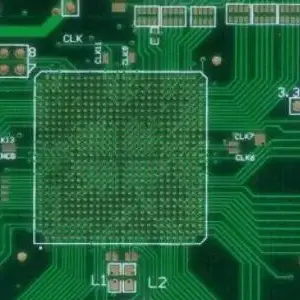

Computer Chips

Circuit boards for cell phones consist of several computer chips. There are digital-to-analog as well as analog-to-digital conversion computers within the circuit board.These chips Analog audio signals are converted into digital signals, which are then converted back to analog signals. The Digital signal processor on the circuit board, which is typically described to have a capacity of 40 MIPS (millions of instructions per second), is used to perform the calculations for signals in a rapid way. It handles the compression as well as the decompression of signals.

Flash Memory and ROM Chips

Flash memory as well as ROM parts of the circuit board of a cell phone, provide storage space that the cell phone uses. They are used to store the customization options of the cell phone and also the complete operating system. The radio frequency and power components that make up the circuit board operate to recharge the phone and also the management of power. It also regulates hundreds of FM channels as well. The RF amplifiers concentrate on signals that pass through as well as out from the antennae on the phone.

Microprocessor

The microprocessor is responsible for executing all tasks that will be accomplished through the display and keyboard. It also concentrates on the phone’s commands (to as well from base stations) and commands. It assists in connecting the keyboard’s various functions.

Why are Multi-Layer PCBs Commonly Used?

Single-layer as well as multilayer circuit boards, are utilized for a variety of purposes. Single-layer PCBs are utilized for basic devices that perform essential features, while a multilayer PCB can be utilized to make more complex devices that have more functions. PCB makers have noticed an increase in demand for multilayer boards because of the requirement for smaller, more intricate devices that can be used in a variety of industries and segments.

Multi-layer PCBs are typically utilized in various electronics for professional use, like computers, smartphones, heart monitoring devices, and many more. Multilayer PCB fabrication involves laminating more than two conductor layers. A variety amounts of layers could exist, depending on the application’s requirements. A higher number of layers within the circuit board permits greater wiring and circuitry for more intricate applications. For instance, mobile phone circuit boards may contain as many as 12 layers since they are extremely complicated devices.

Due to the wide range of multilayer PCBs, they are extensively used in a variety of gadgets, including automotive electronic devices, electronic consumer products, aerospace, and numerous other applications. The use of these printed circuit boards has many benefits.

Contact Unitepcb for Multilayer PCB Manufacturing

The PCB that goes with a mobile phone made by UnitePCB can be used with a variety of components and parts. The latest technology and equipment at the manufacturing facility situated in Shenzhen, China, produce PCBs that are not only durable but give our customers value in the long run. This is due to the fact that our manufacturing processes are ISO9001 and TS16949 accredited. We provide nothing less than the highest quality PCB technology and are a leading manufacturer of PCBs for prototypes as much as production.