Professional Nelco PCB Manufacturer and Supplier

Nelco is a world-class producer and materials of electronic components used for the production of a complicated multilayer printed circuit board as well as an interconnection system. When it is printed circuit boards, Nelco makes top thermal and mechanical high-performance materials, which make them suitable to use for boards with high frequency and performance. All of Nelco’s Nelco electronic products are RoHS conforming.

UnitePCB produces Nelco PCBs featuring high-tech digital microwave and RF primarily for telecommunications and internet structure. UnitePCB Nelco PCB offers excellent thermal resistance and resistance to CAF to ensure the lead-free compatibility of assembly.

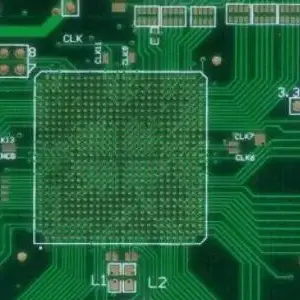

Nelco Printed Circuit Board

Nelco PCB materials are used to make printed circuit boards that have great thermal and mechanical performance. They are good for multi-layer and high-speed digital printed circuit boards. Nelco also makes materials for the RF/microwave industry. These materials offer excellent thermal reliability and CAF resistance. They are also compliant with RoHS regulations and compatible with lead-free assembly.

What Are the Main Properties of Nelco PCBs?

Nelco PCB features great thermal and mechanical properties. The board is suitable for applications requiring precise impedance control and signal integrity. The primary characteristics of Nelco PCBs are:

Lead-free assembly compatibility

Nelco materials are ideal for assemblies with a reflow temperature of 245°C. The reflow temperature could increase to 260degC. This is contingent on the type of construction and design process.

High and loss speed

Nelco PCB has a low dielectric constant and dissipation coefficient. Thus, it is able to be used with low distortion and rapid propagation of signals. For high-performance and high-frequency applications, It is an ideal choose. This PCB is suitable for applications in the frequency range 1-10GHz.

Great thermal stability

Nelco boards provide excellent thermal stability. This attribute explains the capability of Nelco material to keep heat out. Additionally, the glass transition temperature is above 210°C.

Conductive anodic filament (CAF) resistant

This property makes Nelco boards ideal for digital and RF applications. Additionally, it offers the long-term reliability required for these applications.

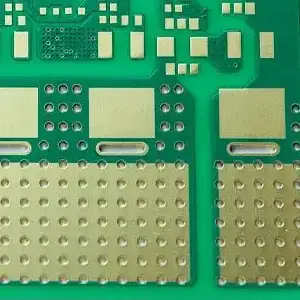

Wide range of constructions

This PCB can be found in various application. And these constructions vary from copper weights to glass styles. Additionally, they are offered in a two mil system.

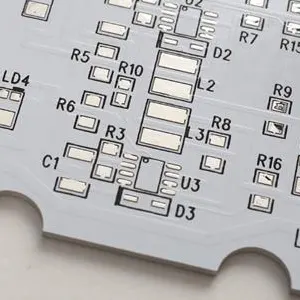

Types of Nelco PCB

● Single-Sided PCB: Single-sided PCBs from Nelco contain only one layer of conductive material and are ideally suited for low-power and low-noise applications.

● Double-Sided PCB: Two-sided Nelco PCB has a two-sided trace on one side and the conducts on the other side. Attach copper and other material to both side of the PCB.

● Multilayer PCB: The multilayer printing circuit board is the technology that permits you to design circuit boards with at least three layers of materials in the middle of the PCB.

● Rigid PCB: Rigid Nelco PCBs come with solid, rigid features that prevent they are being bent or bent to interconnect electronic components of electronic devices.

● Flexible PCB: Flexible-based PCBs that are printed in a patterned arrangement of components. They are designed to work in restricted spaces and are printed on an elastic substrate.

● Rigid Flex Nelco PCB: Flexible-Rigid Nelco PCB is an amalgamation of flexible and rigid circuit boards that can be continuously combined. It promotes stability and flexibility.

Is there Difference between Taconic PCB and Nelco PCB?

The primary distinction between Taconic PCB and Nelco PCB is the primary type of material used on the circuit board.

Taconic PCB mostly uses the PTFE laminate. Nelco PCB applies a variety of different materials like High-Speed Epoxy, FR-4, and High-Tg materials. The PCB also makes use of enhanced materials like cyanate ester BT as well as polyimide.

All PCBs are high-frequency laminates that guarantee a stable dielectric constant as well as a very low dissipation factor.

Designing Your Nelco PCB

UnitePCB will provide you with entire Nelco PCB designs. The design you submit for Nelco printed circuit design will be used as a basis for the design we’ll prototype, fabricate and assembly your printed circuit board.

Thus, it’s beneficial to customers to think about the specifics of the PCB design prior to sending the order to a manufacturer PCB manufacturer.

Important elements that are essential to Nelco PCB design consider PCB stacking copper traces, through-hole varieties, materials for boards (including Nelco PCB finishes), and choice of PCB component’s power and signal integrity as well as design guidelines.

Why Choose Unitepcb’s Exemplary Nelco PCBs?

There are many good reasons to pick Unitepcb’s outstanding Nelco PCBs. Here are a few of them:

● Quality: All of our PCBs are made in accordance with the highest standards, making use of only the finest materials. This produces an item that is durable and durable.

● Service: We offer personal service to each of our customers, making sure that you receive the highest advice and assistance during the entire manufacturing process.

● The flexibility: We understand that every client has different needs, which is why we provide the flexibility of our service, which can be customized to meet your specific requirements.

● Value: The PCBs we supply represent excellent value for money, as we feel that quality should not come at a premium.

UnitePCB – Your Quality Manufacturer of Nelco PCBs

UnitePCB is a company with greater than ten years of expertise in the production of Nelco PCB. Consequently, you can trust Unitepcb to provide you with a complete PCB solution for Nelco. The Nelco PCB is a quality-based PCB that is compliant with the required standards. It has ISO9001:2008, RoHS, REACH, ISO9001:2015, UL(E477880), and ISO14001:2015 certifications. Additionally, it is in line with the requirements of product surveillance, as IPC classes two and three.

We invite you to contact us with your positive feedback, questions, ideas, suggestions, or layouts to us for the best Nelco PCB. We are able to accept OEM as well as ODM services. The delivery team of Unitepcb is experienced when it comes to handling your orders and getting them delivered in the shortest time possible. We are able to work efficiently with integrity, honesty, and professionalism!