Professional High-speed PCB Design and Manufacturing Services

We offer high-speed board design and manufacturing services for electronics. Unitepcb provides a fully integrated high speed capability, with in-house design, simulation, signal integrity, EMC/RFI analysis, prototyping and production of custom backplanes, high speed PCBs, cables and enclosures.

What Are the Materials Used for Your High-speed PCB?

The usual answer is FR4. The PCB board we are talking about usually refers to the substrate. It is actually composed of copper foil and prepreg, and there are many classifications of copper foil and Prepreg according to different applications.

FR4 uses epoxy or modified epoxy resin as the adhesive, and glass fiber cloth as a kind of reinforcing material. That is to say, as long as the material of this system is used, it can be called FR4, so FR4 is the general term for this resin system. Printed boards using FR4 materials are currently the world’s largest and most used type of printed boards.

Generally, FR4 will be classified according to the following types.

1. According to the naming and classification of fiberglass cloth weaving, such as:

106, 1067, 1080, 1078, 2116, 2113, 3313, 7628, etc.

These are commonly used glass cloth types, of course there are others. Each type of glass cloth is defined in the IPC specification. Therefore, the same type of glass cloth used by different PCB manufacturers is basically not much different, because glass cloth also has Many PCB manufacturers, but the same type of glass cloth provided by different PCB manufacturers must meet the requirements of the IPC specification.

2. Classified according to glass type

● E-glass (E-glass): E stands for electrical, which means electrical insulating glass. It is a calcium aluminosilicate glass with little alkali metal oxide content (generally less than 1%), so it is also called alkali-free glass. Has high resistivity. E-glass has now become the most commonly used component of glass fiber, and many PCB material generally use E-glass unless otherwise specified.

● NE glass (NE-glass): Also called low-Dk glass, it is a low-dielectric fiber glass developed by Japan Nitto Textile Co., Ltd., its dielectric constant ε (1MHz) is 4.6 (E glass is 6.6), and the loss factor The tanδ (1MHz) is 0.0007 (E glass is 0.0012), and NE-glass materials are commonly used such as M7NE, IT968SE and IT988GSE.

3. According to the resin system used by the PCB supplier and its performance classification

● Iteq high speed PCB material: IT180A/IT170GRA1/IT958G/IT968/IT968SE/IT988GSE

● Tuc high speed PCB material: Tu862HF/Tu872LK/Tu872SLK/Tu872SLK-SP/Tu883/Tu933+

● Panasonic high speed PCB material: Megtron4/M4S/Megtron6/M6G/M7E/M7NE

● Park Meteorwave series: MW1000/2000/3000/4000/8000

● ShengYi high speed PCB material: S1000-2(M)/S7439/S6, etc.

● Rogers high speed PCB material: RO4003/RO3003/RO4350B (RF materials), etc.

4. Classification according to flame retardant performance

Flame-retardant type (UL94-VO, UL94-V1) and non-flame-retardant type (UL94-HB grade)

After reading the above introduction, what high-speed PCB board do you usually use? Of course I want to hear the name of the material corresponding to the resin system and performance used by the PCB board supplier, such as IT180A/S1000-2/IT968/M4S, etc. According to different losses and materials from different manufacturers, it is mainly based on common medium and high-speed plates that have lower losses than ordinary FR4, while ordinary FR4, such as IT180A, S1000-2/M, Tu752/768, etc., basically have little difference in Df. It is also the Hi-Tg board we currently use most, Panasonic’s Megtron6/M6G, which is used for high speed PCB.

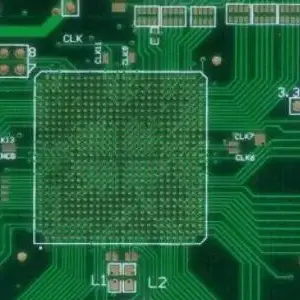

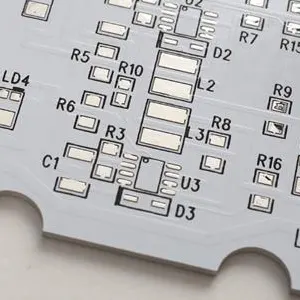

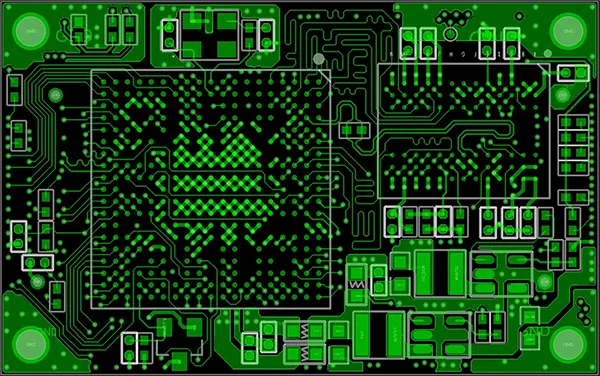

High Speed PCB Design Capabilities

We offer high-speed board design services for electronics. Try our expertise in high-speed, multi-layer, mixed-signal board designs from the block diagrams to all necessary documentation and manufacturing support.

Each project comprise a diverse set of offerings and services, but the overall high-speed PCB design procedure consists of:

● Block diagram

● Design specification

● Library components review

● Schematic design

● Schematic review FW engineer

● Components placement

● Layer stack calculation

● Pre-layout analysis

● PCB routing

● PCB layout review

● Post-layout analysis

● Design documentation development

We take responsibility for each stage of the PCB design procedure, as well as for arising challenges like reduced design time or increased complexity. We make sure you get the best quality design on time and on budget.

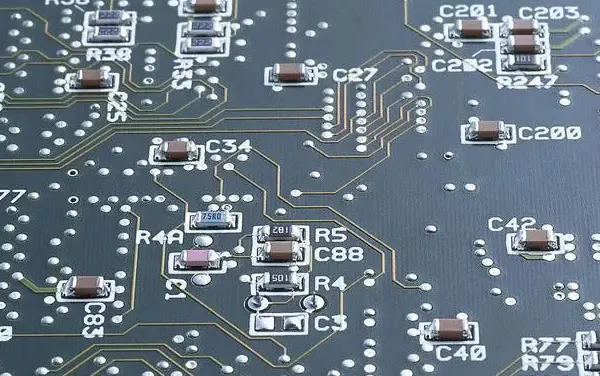

High-Speed PCB Signal Integrity

High-speed/high-frequency PCBs are difficult to design because the signals can easily radiate/couple and affect the signal quality. Here are some points to keep high-speed PCB signal integrity:

1. PCB wires should be short and avoid loops. (don’t make them become antennas).

2. Have a ground layer and power layer to shield signals radiation between layers.

3. Reduce distributed inductance and electromagnetic compatibility of when auto wiring for the key signals.

4. Place the wave filter and decoupling components near the interface.

5. When the circuit board has high, medium, and low-speed signals, keep the high and medium-speed signals away from the interface.

How To Know if You Need a High Speed Design?

1. Is there high speed interface in your board?

A fast method to find out if you need to abide by high speed design guidelines is to check whether you have high speed interfaces, for example DDR, PCI-e, or even video interfaces like DVI, HDMI and so on.

There are some high speed design rules you need to follow for all these interfaces. What’s more, offer the accurate specifications of each data in the documentation.

2. The ratio of your trace length to the wavelength of signals

In general, your PCB will certainly need a high speed design if the wavelength of your message is the same as the trace length. Because some standards such as DDR require traces that have a length matched to minimal tolerances.

A great rough figure is that if your trace length and wavelength can control within one order of each other. Then you’d better check the high speed designs.

3. PCB with wireless interfaces

As you know, each PCB has an antenna, it needs to design for high speed signals no matter what through the connector or on the board. What’s more, onboard antennas also require close impedance to match tune length.

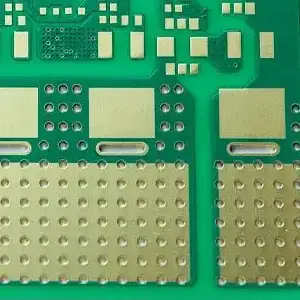

Working With Unitepcb

High-speed PCB is widely used in 5G communication such as 5G base stations and large computer. High-speed PCB circuit board is also one of the core products of Unitepcb. We can provide you with high-speed PCB design, high-speed PCB samples, high-speed PCB manufacturing, SMT of high-speed PCB, and PCB assembly services. Beyond our commitment to reduce signal integrity problems in a PCB design, Unitepcb also offers your business an unprecedented level of service and flexibility.